Back

Back

The four industrial revolutions are characterized by advances in power and technology, which significantly impacted the manufacturing process of the time. The four industrial revolutions were spurred by the discovery and use of coal, gas, electronics and nuclear, and the internet and renewable energy. Since 1765 the manufacturing process has evolved immensely - as new energy sources were discovered and technology advanced [1].

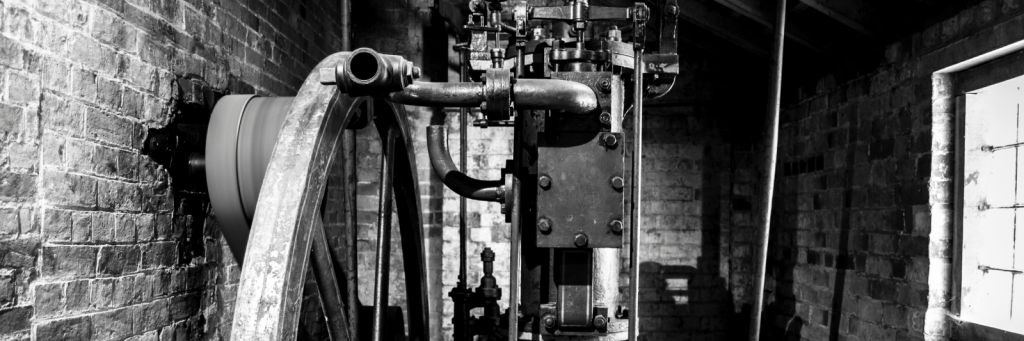

The onset of the First Industrial Revolution took place in 1765. This coincides with the discovery and mass extraction of coal. Using this fuel source, steam power was developed, and the first revolution of industry took place. Production was mechanized for the first time. Steam power and its industrial application resulted in the most significant breakthrough in human productivity ever seen. Before this, labor was powered manually by people and animals. Over the next 100 years, steam power from coal changed manufacturing and changed the way products were transported, affecting the manufacturing supply chain significantly [2].

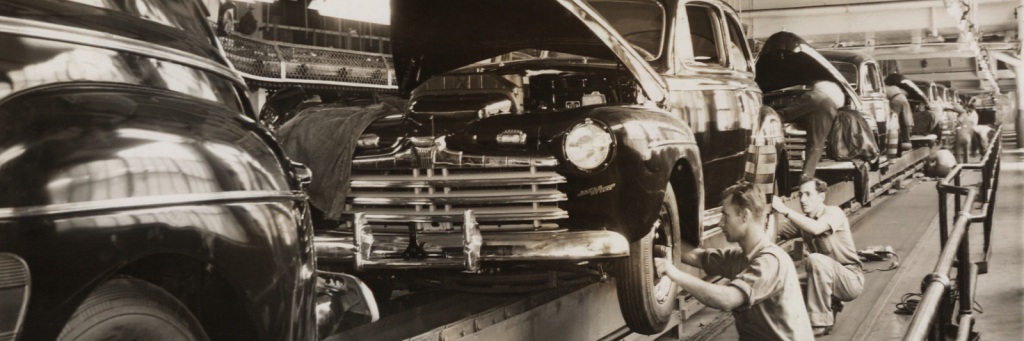

The Second Industrial Revolution began in 1870 and was characterized by the discovery of gas and oil, which powered the advanced technology that created electricity. Other advances during this time, which revolutionized industry, are that the combustion engine was invented, powered by this fuel source, steel, and other new metals entered the market, and Henry Ford developed the assembly line for production. The car and plane were also invented and transformed how products were transported across the country. Manufacturing grew in speed and scaled quickly through mass production and these other revolutions in manufacturing [3].

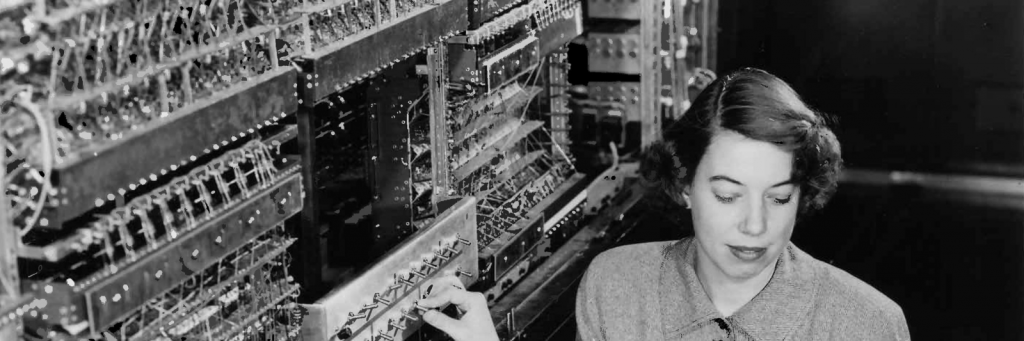

The Third Industrial Revolution began in 1969. This is when nuclear energy and electronics are used to power and advance technology in factories [4]. This is the very beginning of computer technology used to increase productivity in production. Partial automation is also making its debut in this period, as well as memory-programmable controls and computers. Later full automation will develop, and robots will be used in manufacturing [5].

The Fourth Industrial Revolution often referred to as Industry 4.0, began in 2000. Industry 4.0 is defined by popularizing renewable resources for power, like solar panels or wind farms, and integrating the internet into technology, which creates smart factories [6]. The emphasis of Industry 4.0 is the new level of interconnectivity through high-speed mobile internet, artificial intelligence (AI), machine learning, automation, use of big data analytics, cloud technology, and most importantly, the internet of things (IoT) [7]. Industry 4.0 is a holistic approach to manufacturing and allows transparency along the supply chain. This revolution enables business owners to make more informed decisions backed by data and analytics across all aspects of their operations. Industry 4.0 has numerous benefits, including but not limited to increased profitability, productivity, and manufacturing flexibility and customizability; greater efficiency, insight, control, and data visibility across the entire supply chain; faster delivery of products and services to market; higher quality products at a cheaper cost; and reduced errors and delays, through use of predictive maintenance capabilities powered by analytics [8]. These benefits will result in massive savings and revenue generation for companies that are quick to adapt.

How Can Your Company Launch an Online Learning Platform to Prepare for Industry 4.0 Easily and Quickly?

Industry 4.0 is still in the relatively early stages of development. This industrial revolution only started about 20 years ago, and based on past timelines, a subsequent revolution will not develop for about 100 years. The infancy of this revolution is apparent because most companies are still in the beginning stages of adapting to the industry 4.0 business model. The companies who do adopt this model early and embrace the industrial revolution will reap massive benefits. The main obstacle for companies who desire to embrace Industry 4.0 is the lack of skilled labor to control the new technology. The simple answer to overcoming this obstacle and putting your digital transformation into overdrive is to upskill your current workers. The way to do this easily and quickly is to partner with an online learning platform and course provider.

Here are key elements that online learning platforms need to provide value to your company and employees:

With the right partnership, your company can get leaps and bounds ahead of the competition that is waiting for skilled labor to graduate. The proactive approach to digital transformation and Industry 4.0 business models is the smart approach.

Amesite Offers a Single, Easy to Use, Scalable Solution

Launch a platform that helps prepare your company for industry 4.0, increase productivity, revenue, and more!

Amesite is the premier online learning ecosystem provider on the market today. We are well-positioned to provide your business with what it needs to prepare the workforce of the future.

Amesite's platform is high-tech and AI-powered. We specialized in scalable, custom branded online learning environments and content curation to meet employer's unique needs and support the business's upskilling efforts. Artificial Intelligence drives some of the most compelling experiences on the internet, and Amesite brings these tools to education in a novel and transformative way.

Amesite's platform offers excellent insights to learners and employers using advanced data analytics, unparalleled ease of use, features that build communication and engagement, and provides compelling custom content.

Amesite's product is easy to acquire, use, scale, and offers:

Amesite creates outstanding learning experiences delivered on its advanced platform, providing an excellent user experience for employees. Using AI and advanced analytics to provide fresh content creates an important context for learning. Coupled with outstanding services, these experiences deepen professionals' interest in subjects important to their company's goals. Amesite's unprecedented retention rate in the enterprise sector is 100%.

Let Amesite help your company upskill today! Request a Demo!

Check out some of our customer success stories: The Henry Ford, Wayne State University.

Don't forget to subscribe below and follow us on social to be the first to know about new resources, updates, news, and more! Find Amesite on: Twitter, Facebook, LinkedIn, and Instagram!

Resources:

[1,2,4, 6] UpKeep. Oct. 14, 2019. What Are the 4 Industrial Revolutions? https://www.onupkeep.com/answers/maintenance-history/four-industrial-revolutions Accessed May 26, 2021.

[8] Epicor. What is Industry 4.0—the Industrial Internet of Things (IIoT)? https://www.epicor.com/en-us/resource-center/articles/what-is-industry-4-0/ Accessed May 24, 2021.

[7] Change. 2018. How Will the Fourth Industrial Revolution Impact the Future of Work? https://www.changerecruitmentgroup.com/knowledge-centre/how-will-the-fourth-industrial-revolution-impact-the-future-of-work Accessed April 27, 2021.